PCB Trace Width vs. Current: A Guide to Optimal Design

Navigating the complex relationship between PCB trace width and its current carrying capacity is critical for designers who prioritize the durability and reliability of their electronic circuits. This article draws on the IPC-2221 standard to shed light on this vital aspect of PCB design, aiming to enhance both the understanding and application of these principles.

Reference Table

Below is a table based on IPC-2221 calculations. This resource provides a quick glance at recommended trace widths for 1oz copper, adjusted for temperature rises of 5°C, 10°C, and 20°C. If you're unsure where to start, it is recommended to initiating designs with a 6 mil trace width.

| Current (A) | ||||

|---|---|---|---|---|

| Trace width mm | Trace width mil | 5'C | 10'C | 20'C |

| 0.076 | 3 | 0.272 | 0.368 | 0.5 |

| 0.102 | 4 | 0.335 | 0.454 | 0.616 |

| 0.127 | 5 | 0.393 | 0.533 | 0.724 |

| 0.152 | 6 | 0.449 | 0.609 | 0.826 |

| 0.203 | 8 | 0.553 | 0.75 | 1.018 |

| 0.254 | 10 | 0.65 | 0.882 | 1.196 |

| 1.016 | 40 | 1.776 | 2.409 | 3.268 |

| 2.007 | 79 | 2.909 | 3.946 | 5.353 |

| 4.013 | 158 | 4.808 | 6.522 | 8.848 |

| 10.008 | 394 | 9.325 | 12.65 | 17.161 |

The Role of Trace Width in PCB Design

The choice of trace width significantly influences a PCB's functionality and safety. Following the IPC-2221 guidelines helps designers balance the current carrying capacity with the physical dimensions of the board, mitigating risks of overheating and potential damage. This careful consideration ensures the board's performance under operational stresses while maintaining its structural integrity.

The Value of Starting with a 6 Mil Trace Width

When it comes to PCB manufacturing—particularly in prototyping or cost-sensitive projects—the use of a 6 mil trace width is recommended. This is a typical value that is commonly specified by low-cost PCB producers, who typically set a minimum track width of 6 mil. Opting for this standard from the beginning of the design process harmonizes with the production capabilities of a broad spectrum of low-cost PCB manufacturers.

Other Values: IPC-2221 Trace Width Calculator

For those needing values beyond the standard recommendations, referring to an IPC-2221 trace width calculator is suggested. Several online tools are available, offering detailed calculations to help designers find exact trace widths for any given current and temperature rise scenario.

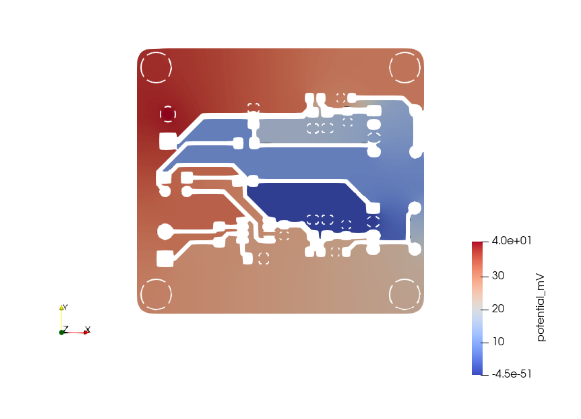

Addressing Complex Trace Temperatures with FEM-Based PCB Simulation

Tackling the temperature rise in complex trace configurations can be challenging. To navigate this, consider utilizing our FEM (Finite Element Method) based PCB simulator. This advanced tool allows for precise simulations of temperature rises across intricate trace layouts, providing invaluable insights into the thermal performance of your PCB. By leveraging this technology, designers can make informed decisions, ensuring optimal functionality and reliability in their final products.

Click here to use our FEM-based PCB simulator